Mosaic™ System for Plasma Dicing

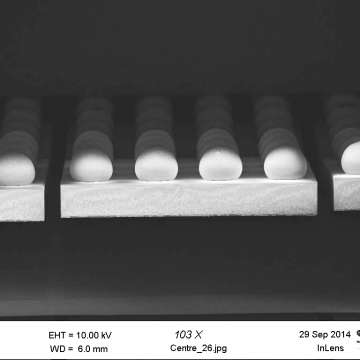

The Mosaic™ platform with Rapier-S process modules, is an etch system, designed for plasma dicing of framed wafers up to 200mm, in volume production. The larger Rapier-300S module is compatible with 300mm framed wafers.

- Mosaic platform is based on the existing range of SPTS platforms for Omega, Sigma & Delta products.

- Rapier-S/Rapier-300S systems are an evolution of the Rapier DRIE product line, bringing DRIE capability to framed substrates.

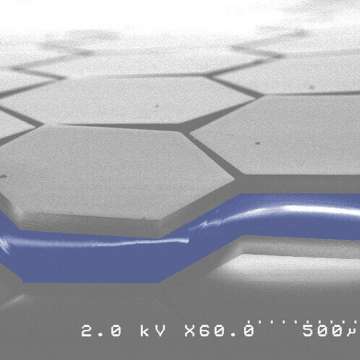

- High throughputs are achieved with Rapier-S/Rapier-300S. The flexibility of the Bosch process provides ability to etch narrow, high aspect ratio lanes up to “full wafer thickness”.

SPTS’s Sentinel™ end-point detection system (patent-pending), detects the point at which the etch first reaches the dicing tape, and also any loss of active cooling during the process. At end-point, the process can be modified to complete the die separation without causing lateral damage of the die sidewall at the silicon/tape interface. This control ensures that die strength is improved compared to existing singulation methods. Use of end-point detection also protects the tape, ensuring that singulated die can be safely handled and the tape frame re-used.