Claritas - Unique End-point Solution for Deep Silicon Etch

Introduction

End-point detection is critical for knowing when a plasma etch process has ended. It is an essential part of delivering repeatable results on every wafer.

Optical emission spectroscopy (OES) uses light emitted from the plasma during etching processes to detect by-products. When the etch reaches a stop layer the plasma chemistry changes and detection of this difference indicates an ‘end-point’.

Challenges for End-pointing Deep Silicon Etching

OES end-pointing is routinely used for standard semiconductor etch processes, but for deep silicon etching it is particularly challenging. There are 3 principal factors:

- The DRIE/Bosch process continuously alternates between silicon etching and polymer deposition cycles. End-point detection therefore needs to be ‘gated’ so it only takes an appropriate section of each etch step

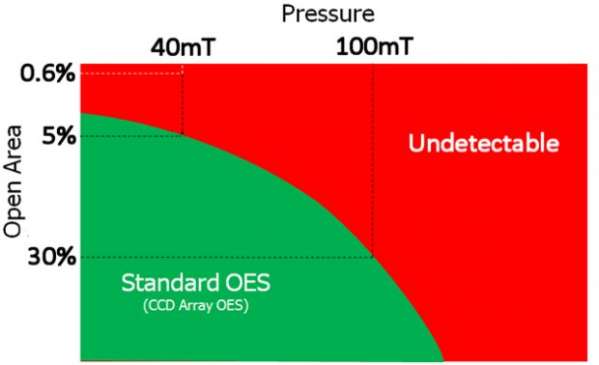

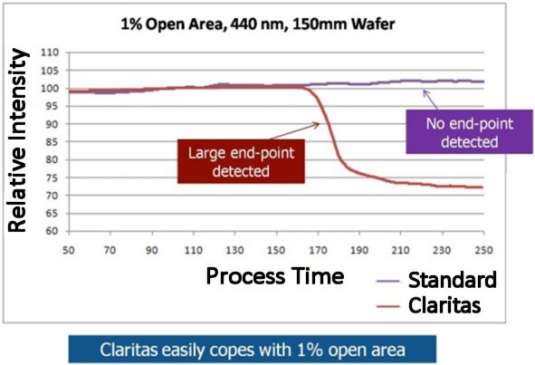

- If open area is low (<5%) the signal change at endpoint is naturally reduced.

- Relatively high pressures are used to drive up the etching rate, and this tends to force the etch by-products into inaccessible regions of the process chamber and may also remove the excited electronic states that cause light emission. This effect occurs irrespective of open area.

For these reasons, standard OES set-ups cannot easily detect end-points across the broad range of deep silicon etches used in MEMS manufacture.

SPTS offers Claritas™, an end-pointing solution specifically designed for deep silicon etch processes, based around a conventional CCD array OES spectrometer with a proprietary combination of hardware, and software algorithms.

Benefits of Claritas™

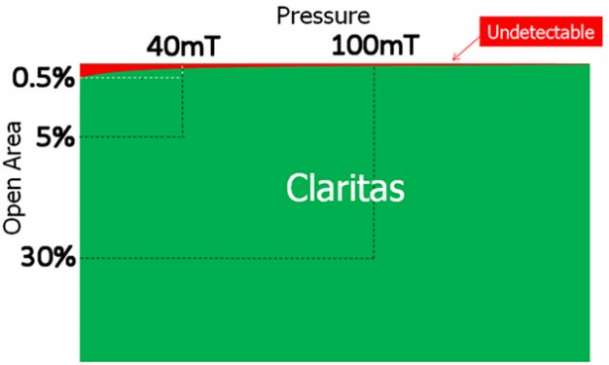

Allows virtually any deep silicon etch to be end-pointed, irrespective of pressure, down to an open area ~0.4%.

Allows virtually any deep silicon etch to be end-pointed, irrespective of pressure, down to an open area ~0.4%.- Detects when features with varying sizes on the same wafer (that naturally etch at different rates) reach a stop layer at different times during the process.

- Improves wafer yields through the provision of repeatable end-pointed processes

- Eliminates or reduces the need for costly and destructive cross-sectional wafer analyses

Claritas™ is available on current Rapier DRIE modules or as an upgrade to existing SPTS DRIE equipment.

Information on this page contains forward looking information. For more information, click here