Morflex – Flexible Process Control for MEMS & TSV etch

Silicon MEMS structures are typically formed using Deep Reactive Ion Etch (DRIE), also known as the Bosch Process. This is the best solution for etching deep, vertical, high aspect ratio features in silicon, at a high rate. The same process technology is also being utilised to form through silicon vias (TSVs) in advanced “3D-IC”and “2.5D” packaging applications.

However, as any feature is etched deeper into the silicon the etch conditions change, because the transport of reaction species and by-products in and out of the feature becomes less efficient. This leads to a mixed, non-optimal chemistry at the etch front with a potential reduction of etch rate, undesirable profiles and degraded uniformities as a result.

To combat this effect, and to maintain the etch rate and vertical profile of the feature, it is necessary to compensate for the change in process conditions as the etch progresses.

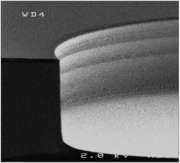

DRIE process conditions can be changed in a series of steps, or blocks, within a process recipe. However, this can add time to process development, and lead to undesirable “seams” in the sidewall. (see figure 1)

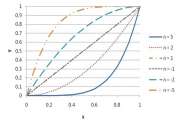

SPTS offers a unique and patented “parameter ramping” technology, using its MorflexTM software, which allows continuous adjustment of the plasma conditions (see figure 2).

Fig 1: Cavity etch with “seams” resulting from stepped DRIE process

Fig 2: Graph illustrating flexibility of Morflex software to control 2 plasma parameters in a linear or non-linear relationship.

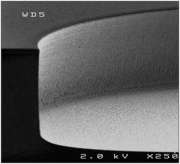

Fig 3: Cavity etch using process controlled by Morflex software

By using MorflexTM, manufacturers can simplify process recipes and produce the smooth vertical sidewalls (see figure 3) required for high aspect ratio features in MEMS and advanced packaging applications. Morflex is only available on SPTS’ DSi & Rapier DRIE systems, including 300mm-compatible models, and can be taken as a field upgrade.

For more details on Morflex, please contact your local SPTS Sales office.

For more details on SPTS’s DRIE products.