MEMS

Micro Electro Mechanical Systems (MEMS) are microdevices used in a wide range of consumer, automotive, medical and industrial products, for example, smartphones, microphones in smart speakers, airbag sensors, gyroscopes, navigation systems, game consoles, and biomedical devices.

MEMS device manufacturing covers a wide range of applications and materials, where often bespoke processes are used to create life-enhancing devices.

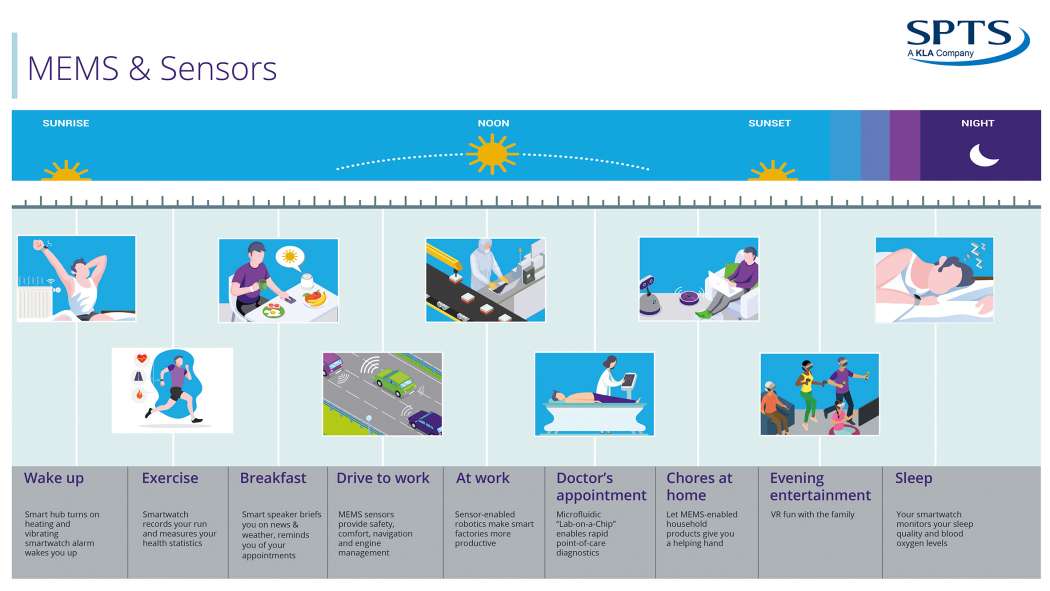

Do you realize how often you encounter MEMS devices every day? Click on the image to enlarge this infographic.

SPTS Technologies is the leader in the supply of enabling wafer processing systems to the MEMS community, serving the industry since the emergence of the first silicon MEMS in the 1990s.

MEMS Processes:

- Si DRIE - high rate, deep silicon micromachining, with excellent profile control

- Release Etch - stiction-free, corrosion-free release of MEMS by dry vapor etch using HF or XeF2 to remove sacrificial layers of oxide or silicon.

- Plasma Enhanced Chemical Vapour Deposition (PECVD) - low temp PECVD for deposition of low stress SiN and SiOx

- Physical Vapor Deposition (PVD) - AlN/AlScN deposition with excellent stress control and thickness uniformity for RF and piezoMEMS

- Molecular Vapor Deposition (MVD) - deposition of thin, anti-stiction/corrosion coatings